The field of AI is advancing rapidly, with ongoing improvements in AI models and sensors presenting exciting prospects for enhancing manufacturing and design processes. This expansion of AI has the potential to greatly improve how we approach conception, creation and building, resulting in innovative and efficient developments in these areas. As AI techniques mature and become more accessible and widespread, its impact is likely to grow.

Traditional methods of controlling processes typically rely on predetermined models and rules that are often based on historical data and human expertise. However, these methods have limitations, particularly when it comes to dealing with the increasing complexity, variability and unpredictability of modern manufacturing processes and the world they operate in. Also, these methods generally do not make the most of the enormous amounts of data that can be generated by modern sensors and systems in real time.

This is where AI comes in. To clarify what we are talking about here, AI is (broadly) the ability of machines to do things that we ordinarily think of as requiring human intelligence. AI boils down to mathematical relationships between variables, so we usually describe specific instances of AI programs or algorithms as “AI models.”

In the past decade, a branch of AI called machine learning, where models learn to improve their performance from data rather than explicit programming, has become very prominent. More recently, this has been augmented by the rise of foundation models and generative AI.

Foundation models are large models that have been trained on very large data sets, which can be adapted to a variety of tasks. Generative models learn how to create new content, such as text or images, based on the existing data that they are given. The confluence of these trends in the form of ChatGPT and similar models has propelled AI into the mainstream in ways not seen before.

Potential benefits of AI

Improving productivity

Often, manufacturers have more data than they know what to do with, and data fuels AI. By analyzing vast amounts of data, hidden patterns, anomalies and insights can be discovered. The discovered relations may then be used to enable a better understanding of processes to make more informed decisions. This can optimize process performance and reduce downtime.

Enhancing quality, resilience and sustainability

AI can help manufacturers to monitor and maintain the quality of their raw materials, products and equipment by detecting and responding to defects, anomalies and errors in real time. With increasing data and sophistication, this can allow you to use new materials more quickly should supplies be interrupted and to effectively use natural or recycled materials, which can feature variable properties.

Increasing innovation and competitiveness

AI techniques can help with design of better products, services and business models. This can include better product designs, for example, driven by rapid and efficient data-driven simulations and more rapid reconfiguration driven by supply and demand. In the future, AI could even help to break down siloed knowledge across design, manufacturing and supply chains, leading to a step change in capabilities.

Reducing waste

AI techniques can reduce waste related to materials, energy, time and space. This can take several forms, from coupling in-process monitoring with anomaly detection to repair defects or discontinuing work on a failed part, to using AI to operate processes in ways that minimize energy or material use.

Empowering humans

AI systems can augment workers’ knowledge by making the most relevant expert insights readily available. AI could also aid communication and coordination with customers and suppliers, for instance, using chatbots.

Tips on how to adopt AI successfully for process control

Implementing AI for process control is no trivial task. It requires careful design, testing and deployment. It also requires continuous evaluation. Here are some tips to help you hit the ground running.

- Define your goals and metrics. Before you start using AI for process control, you need to have a clear vision of what you want to achieve and how you will measure your success. You should define specific goals and key performance indicators that align with your business objectives and customer expectations.

- Understand your data. Data is the foundation of AI models. Without good data, you cannot build good AI systems. You must understand the available sources and what types, formats, quality, biases and availability these may offer. Generally, more data is better, but often a small, clean data set can provide more information gains than a large, noisy and biased one. Finally, be sure to protect your data sources. AI models are often very vulnerable to adversarial attacks that can degrade decision-making.

- Choose the right AI techniques. Many different AI techniques can be used for process control, and new ones are continuously being invented. You must choose the right AI techniques to suit your data characteristics, process requirements and goals. You also need to consider the trade-offs between the complexity, accuracy, speed, scalability and interpretability of your AI techniques. It is often best to use the simplest technique that gives you acceptable results.

- Validate and verify your AI systems. Before deployment for process control, you will need to make sure that the system works as expected. Validate and verify by quantifying how well it satisfies the metrics you defined earlier. Generally, the point of an AI system is for it to make useful predictions in situations it hasn’t seen before. Therefore, it is very important to evaluate the system on data that it has not previously seen. Also, AI-based systems can behave in unpredictable ways, so it is best to build in safeguards to control such risks.

- Monitor. After deployment, you need to monitor and improve your framework on a regular basis. To monitor the results, a good dashboard providing you with reports, alerts and logs will greatly help.

Case study: AI systems for process control

Together with my team at the IfM’s Computer-Aided Manufacturing Group, we develop AI-based systems to control a wide range of manufacturing processes. We specifically look to develop systems that can easily transfer from one system to another.

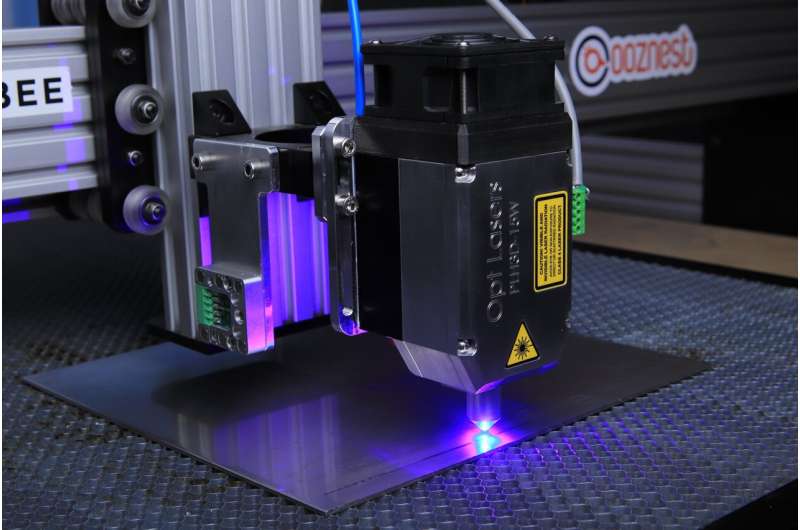

We typically use vision sensors placed in and around the system to give the AI model similar views to what a human operator might see. This can then be supplemented with readings from sensors already integrated into the system and any other data necessary to assess process quality.

Our work so far is the most advanced in additive manufacturing. Extrusion 3D printing is a popular additive manufacturing technique that builds objects by depositing layers of molten material, usually plastic, through a nozzle. Extrusion 3D printing has many applications in sectors such as medical devices, automotive and construction. It faces challenges, mostly in terms of the accuracy, consistency and quality of the printed parts.

In this case, we typically use vision sensors mounted on the printer nozzle and frame so that the AI model can see what is going on. In one recent work, we created a data set that includes various instances of print errors and how to fix them. We presented this data set to an AI model, which learned to identify each type of error and take appropriate actions to resolve it. This allowed for closed-loop control of the process.

We are working to translate this method into other manufacturing processes and to make it more effective, for instance, by enabling it to learn to prevent errors.

University of Cambridge

Citation:

Machining the future: The AI advantage (2024, November 11)

retrieved 11 November 2024

from https://techxplore.com/news/2024-11-machining-future-ai-advantage.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.